Knowledge & Experience

Highly qualified team, many with over 25 years service

Highly qualified team, many with over 25 years service

48 hours from sample, to finished product

Over 55 years of manufacturing & development

Dry blasting/shot blasting, is a more aggressive cleaning process than our Ultrasonic or Aqua blasting processes.

Mainly used with glass bead or chilled iron granules as a media to remove paint, rust and oxidation on ferrous and non-ferrous metals.

Dry blasting is also used to prepare metals prior to coating & is ideal for removing layers of paint from car / motorcycle parts providing

a key for painting or for cleaning up heavily rusted parts, gates and railings.

Items from as small as door handle to as large as commercial vehicle fuel tank can be dry blasted. The process works particularly well on the following metals:

∘ Steel

∘ Aluminium

∘ Stainless steel

Items need to be degreased in our ultrasonic tanks before the blasting process can be undertaken, Roller bearings, valve gear and other moving parts must be removed.

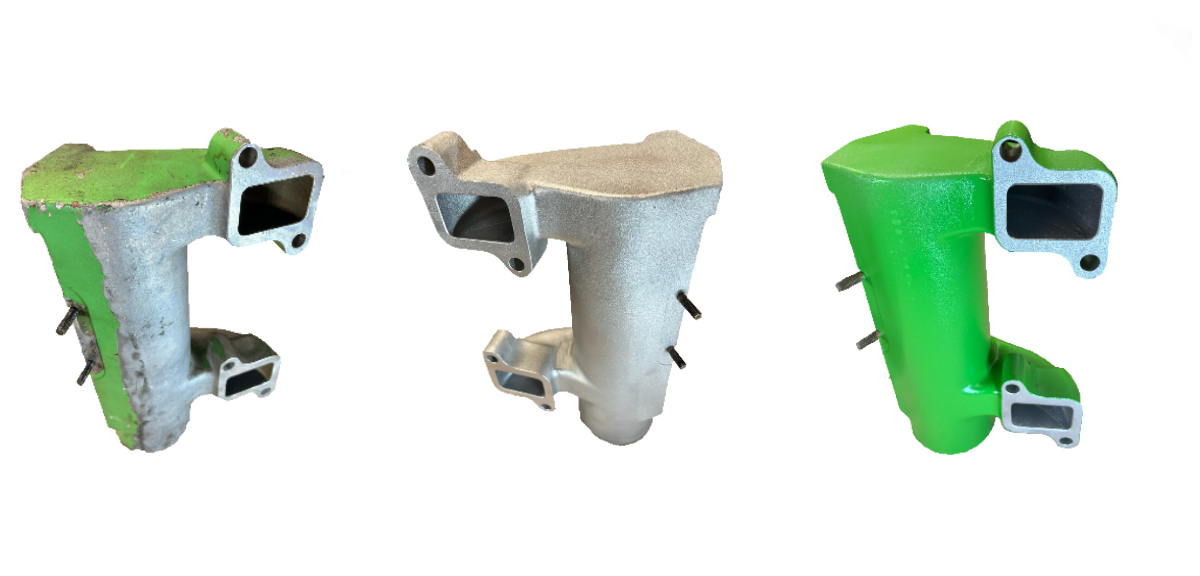

Before & After Dry ShotBlasting of Jenbacher Gas Engine Parts

We have worked with G&M since the late 80s. Their products are of very good quality, their service is great and the team consists of experienced people who have often worked at G&M for so long that they really know what they are talking about. That is why G&M is a great partner in radiator business.

I have been a customer of G&M for over 45 years. The quality and range of the products and the expertise of the staff is second to none

We have worked together with G&M for over 20 years. The knowledge and helpfulness of the staff has been a major factor in developing a very successful business relationship.

First class service. Designed, manufactured and delivered on time and on budget. G&M pulled out all of the stops to deliver a quality product within a tight deadline.