Knowledge & Experience

Highly qualified team, many with over 25 years service

Highly qualified team, many with over 25 years service

48 hours from sample, to finished product

Over 55 years of manufacturing & development

Using high-frequency signals creates millions of miniature bubbles every second. These

bubbles collapse as quickly as they are produced, creating energy in the form of heat and pressure waves.

The pressure waves are capable of reaching into every tiny gap whilst blasting contaminants such as carbon,

oil & grease from all types of surfaces including metals, alloys, plastics, filters & ceramics.

The power of our equipment can be harnessed to clean items of all shapes, sizes & technical complexity,

penetrating holes & cavities that are impossible to reach using ordinary cleaning methods.Ultra Sonic Solutions - Ultrasonic Cleaning

Ultrasonic Baths

Ultrasonic Parts Cleaning Service

Industrial Ultrasonic Cleaning Service

Ultrasonic Cleaning Chemicals

Removing industrial scale calcium deposits

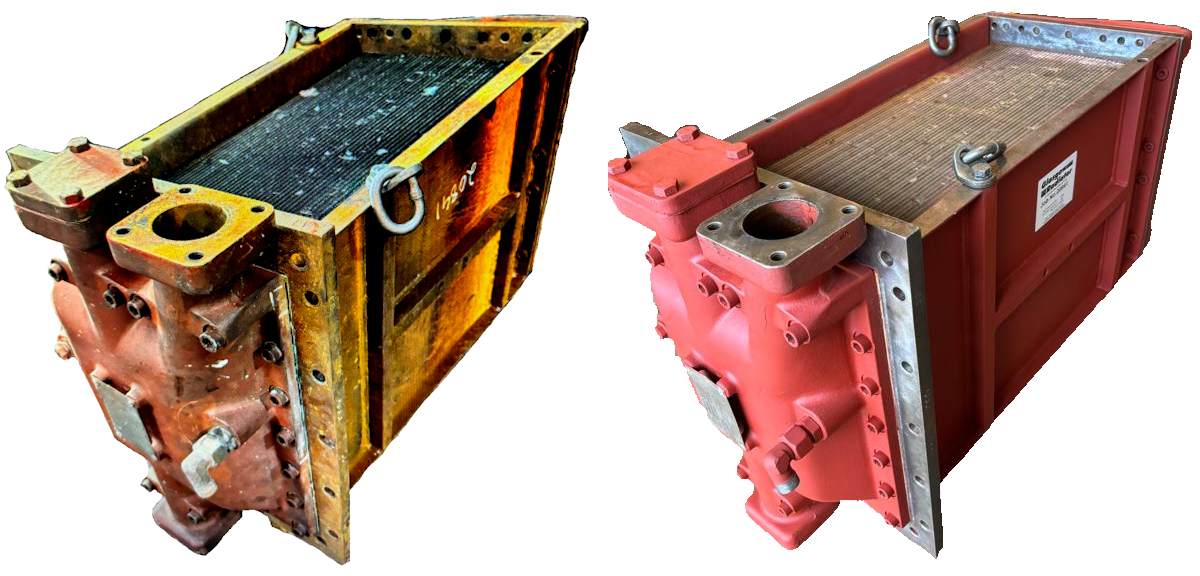

Removing rust and carbonised oils from the tubes and other cavities within heat exchangers

UK specialist ultrasonic cleaning provider

Oil & Gas ultrasonic cleaning

Power Stations ultrasonic cleaning

Engineering ultrasonic cleaning

Aerospace ultrasonic cleaning

Automotive ultrasonic cleaning

Ultrasonic Cleaning Services in Glasgow

We can provide a cleaning and maintenance plan to include the following:

∘ Visual inspection upon arrival.

∘ Weighing of parts before & after work is carried out.

∘ Inspection & assessment using NDT, thermal and internal scope cameras

∘ Dismantle, pressure wash, inspection & report.

∘ Ultrasonic cleaning in one of our purpose built cleaning tanks.

∘ High pressure cleaning.

∘ Rinsing in one of our purpose-built rinse tanks

∘ Chemical cleaning

∘ Brushing through internals of tubes.

∘ Shot blasting of case work

∘ Vacuum test of individual tubes.

∘ Manufacture of Gaskets

∘ Hydrostatic or pneumatic pressure test of assembled heat exchangers.

∘ Manufacture of anodes & tapered tube plugs.

∘ Internal coatings of water boxes.

∘ Oven dry & paint of parts.

∘ Final Qa, inspection and certification.

∘ Dedicated crates & transport

∘ Ultrasonic Cleaning of Marine Charge Air Coolers.

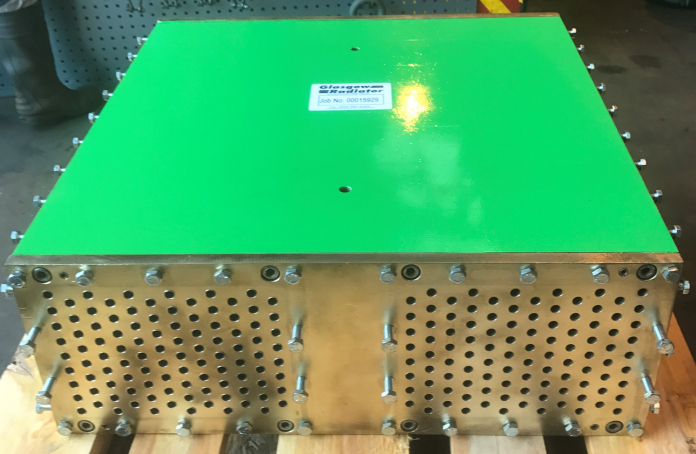

Before & After Ultrasonic Cleaning of a Marine Charge Air Cooler

We have worked with G&M since the late 80s. Their products are of very good quality, their service is great and the team consists of experienced people who have often worked at G&M for so long that they really know what they are talking about. That is why G&M is a great partner in radiator business.

First class service. Designed, manufactured and delivered on time and on budget. G&M pulled out all of the stops to deliver a quality product within a tight deadline.

I have been a customer of G&M for over 45 years. The quality and range of the products and the expertise of the staff is second to none

We have worked together with G&M for over 20 years. The knowledge and helpfulness of the staff has been a major factor in developing a very successful business relationship.